What is a PLC

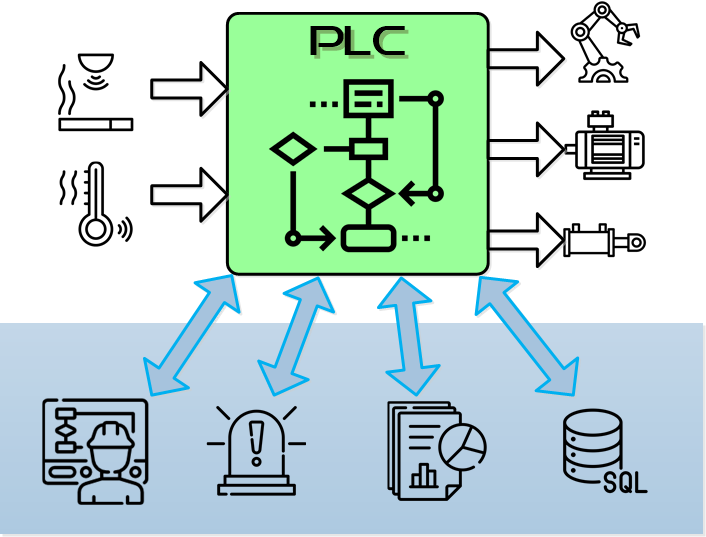

It essentially has:

- Inputs connected to different detection and measurement elements: photocells, inductive, transducers, etc.

- Outputs controlling actuators such as solenoid valves, motors, servos, inverters, etc.

- Communication with other elements: operator screens, alarm centres, report generators and databases.

Once the industrial process to be carried out has been defined, the next step is to design the automation that will carry it out.

And within this automation, the PLC will be in charge of orchestrating all the elements involved and controlling the variables of the process.

In this way, it can carry out the control required by the industrial process.

The programme and its parts

Making a good programme is not only about getting it right at a given time, but also about being able to introduce changes quickly and safely.

While every programmer has his or her own style, there are certain methodologies that allow for greater flexibility and reliability in changes.

Well-established best practices in the IT industry such as SOLID, DRY and Hexagonal Architecture among others can be applied.

The use of the following is also appreciated:

- Naming conventions for variables and functions

- Clear and concise comments

-

Priority to code portability

- Modularity, reusability and scalability

- Focusing development on performance testing

Ultimately, good software is achieved with solid methodologies, modularity, reusability, scalability and exhaustive testing.

Where to improve

Reduce cycle time

Time is money, and reducing machine cycle time translates into direct gains.

New models

The market demands new features and new models. We can update the programme to accommodate them.

Remove obsolete parts

Often obsolete parts are left behind "just in case". This slows down and hinders future planned changes.

Reduce energy costs

Processes can be optimised to minimise their energy consumption.

Flexibility

Being able to make changes quickly and with the assurance that they will not affect other parties.

Automatic data extraction

The data is sent in real time to the database to be analysed with programmes such as PowerBI or Tableau.

Quality Assurance

Registra las comprobaciones y pokayokes desactivados en las líneas. Evita rechazos del cliente.